It uses GPS to locate the scanner position (GPS horizontal positioning error of 1 cm, elevation error of 2 cm). It is a new type of high-precision pannier system developed by using two-dimensional scanner to scan the inclination distance at high speed, using multi-sensors for precise lateral angle measurement, combined with mapping and three-dimensional graphics processing technology, which greatly improves the problems of the original old pannier in the market by forming an encoder to measure the distance error is too large, vertical angle, low accuracy of encoder angle measurement. This system can be applied to the volume measurement of any shape of pile material and is a reliable front-end collection device for digital coal yard.

It adopts the mature laser-time flight principle, non-contact detection, IP67 protection level and internal integrated heater, which makes it possible to be used in outdoor harsh environment for area collision prevention and measurement, and the measuring distance is 250 meters (150 meters at 10% reflectivity). 150m), data interface RS422 and Ethernet interface, PNP open-drain output.

Working principle and process

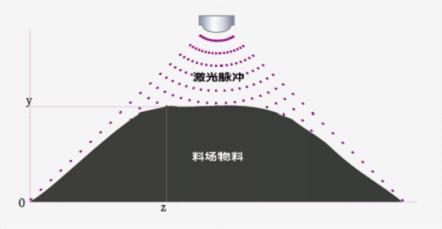

1.1 The system takes the stacker reclaimer (cantilever stacker reclaimer as an example: Figure 1) as a carrier and uses laser scanning ranging technology and position sensing technology to instantly acquire the spatial position information data of the measured material field and transmit it to the computer platform simultaneously. One of the key aspects of this system to collect data is to scan the material surface by the laser scanner's two-dimensional sector to obtain the angle information and distance information between the measured coal yard and the laser scanner (Figure 2)

Figure1

Figure2

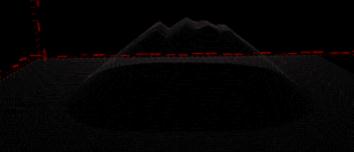

Figure3

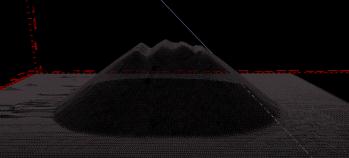

Figure4

Figure5

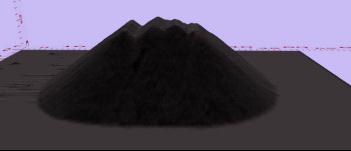

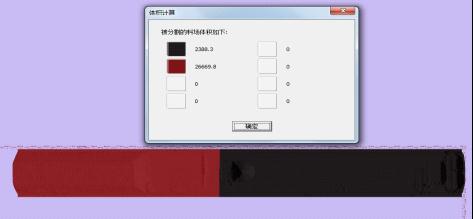

1.3 By constructing an irregular triangular network, the measured material shape is decomposed into tens of thousands of trigonal prisms, the volume of each trigonal prism is calculated, and the volume of the measured material is obtained by accumulating the volumes of all trigonal prisms (Figure 6). At the same time, the software can realize the calculation of the partition of the measured object (Figure 7).

Figure6

Figure7

Features of the product.

The relative accuracy and absolute accuracy of the system has the characteristics of high precision volume error can reach within six thousandths.

Fully automatic scanning, fast measurement speed.

IP67 waterproof can work all-weather measurement accuracy is not affected by human factors weather factors, the shape of the pile.

Software operation is simple.

Single person can complete the operation.

Long detection distance (250 meters)

High angular resolution (0.125 degrees)

Large scanning angle (Max: 300 degrees, can be adjusted in the setting parameters)

Measurement principle.

This product adopts two-dimensional high-speed laser scanner to collect high-density cross-sectional data on the coal pile combined with GPS system and sensors to obtain the spatial coordinates and angular information of the scanner to achieve three-dimensional point cloud collection three-dimensional graphical display and can be output by report and graphic printout of the pile volume measurement system.

Application areas.

Thermal power enterprises, port terminals, steel plants, metallurgical units, chemical enterprises, construction earthwork excavation sites, open pit mining sites, rock profile measurement.

Installation location.

Can be installed in open pit bucket wheel, gantry crane, bridge grip, round coal yard stacker reclaimer, various other mechanical platform coal yards (non-open pit is not applicable to GPS).

Equipment composition.

|